Projects

Monitoring and Maintenance of Production Line Equipment Using Laser Marking Technology on an IoT Platform

- Engraving QR-Codes and required information on various fixed and portable parts and equipment

- Recording purchase documents, installation and operation instructions, repair, inspection, and calibration information in a database on the IoT platform

- Retrieving part information by reading QR-Codes and connecting to the database via mobile phones or dedicated devices developed by this company with high security

- Access level control based on user type, IP, and geographical location

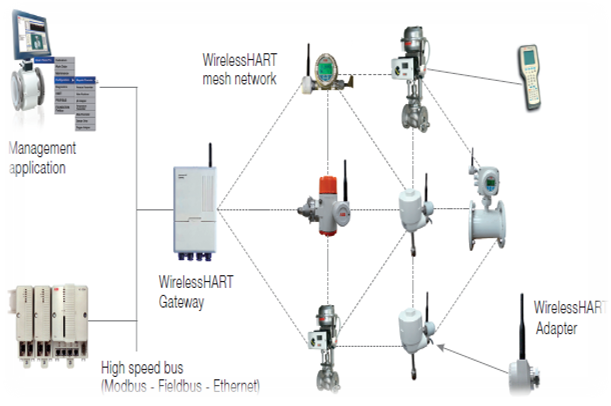

Design and Implementation of Wireless Instrumentation Network (Wireless HART), executed at National Gas Company and Isfahan Power Plant

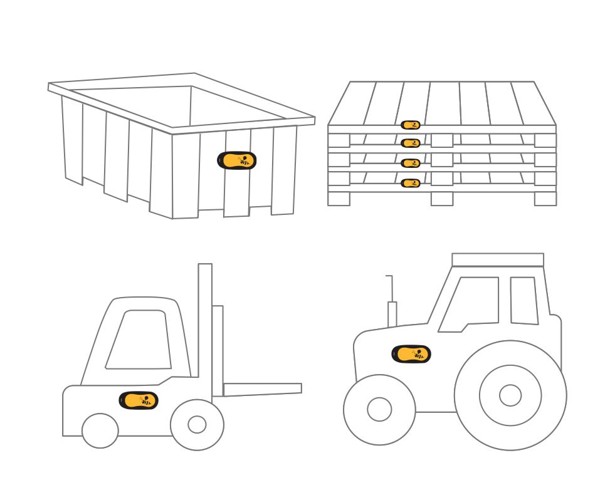

Identification of Steel Sheet Roll Storage Locations, executed at Mobarakeh Steel Complex and Home Appliance Industries

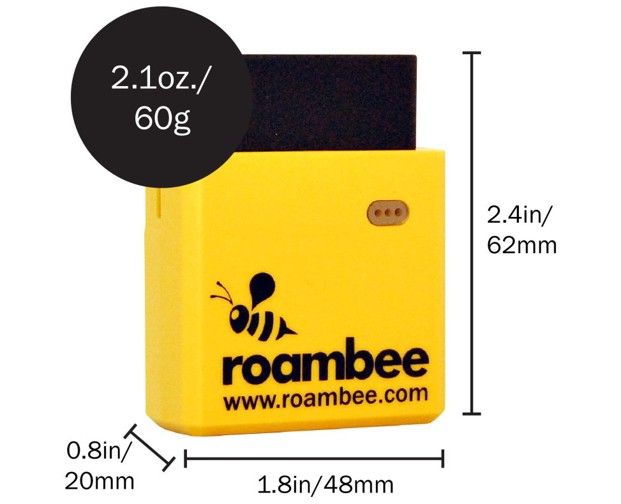

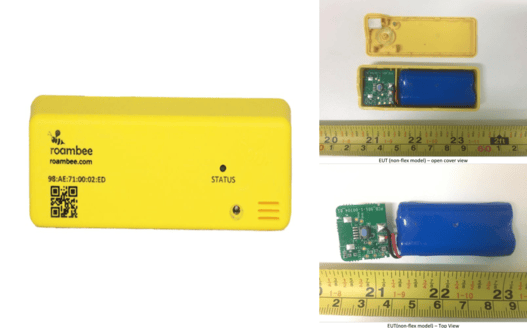

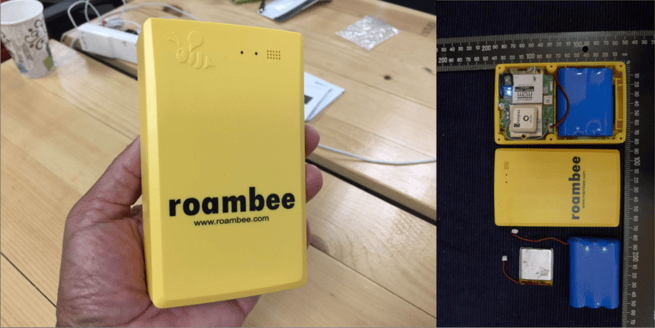

Pallet and Machinery Tags

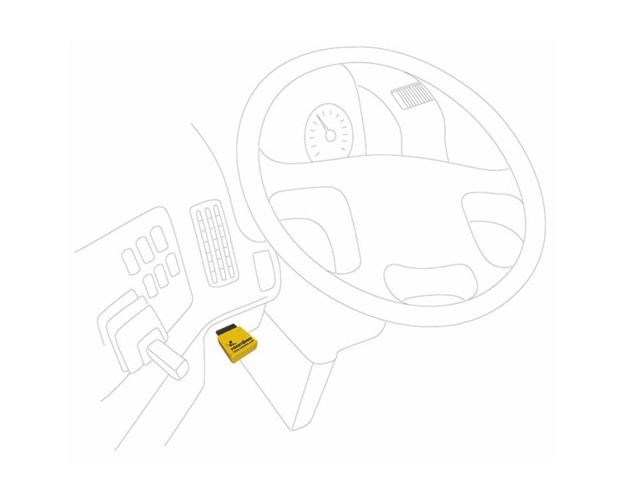

Tags with Ability to Connect to Machinery Controllers