Level 2 Automation of Run-out Table

Cooling the sheet after hot rolling is important, so producing high-quality and valuable sheets requires cooling based on a favorable temperature profile for each steel grade. Therefore, this project was defined in line with the goal.

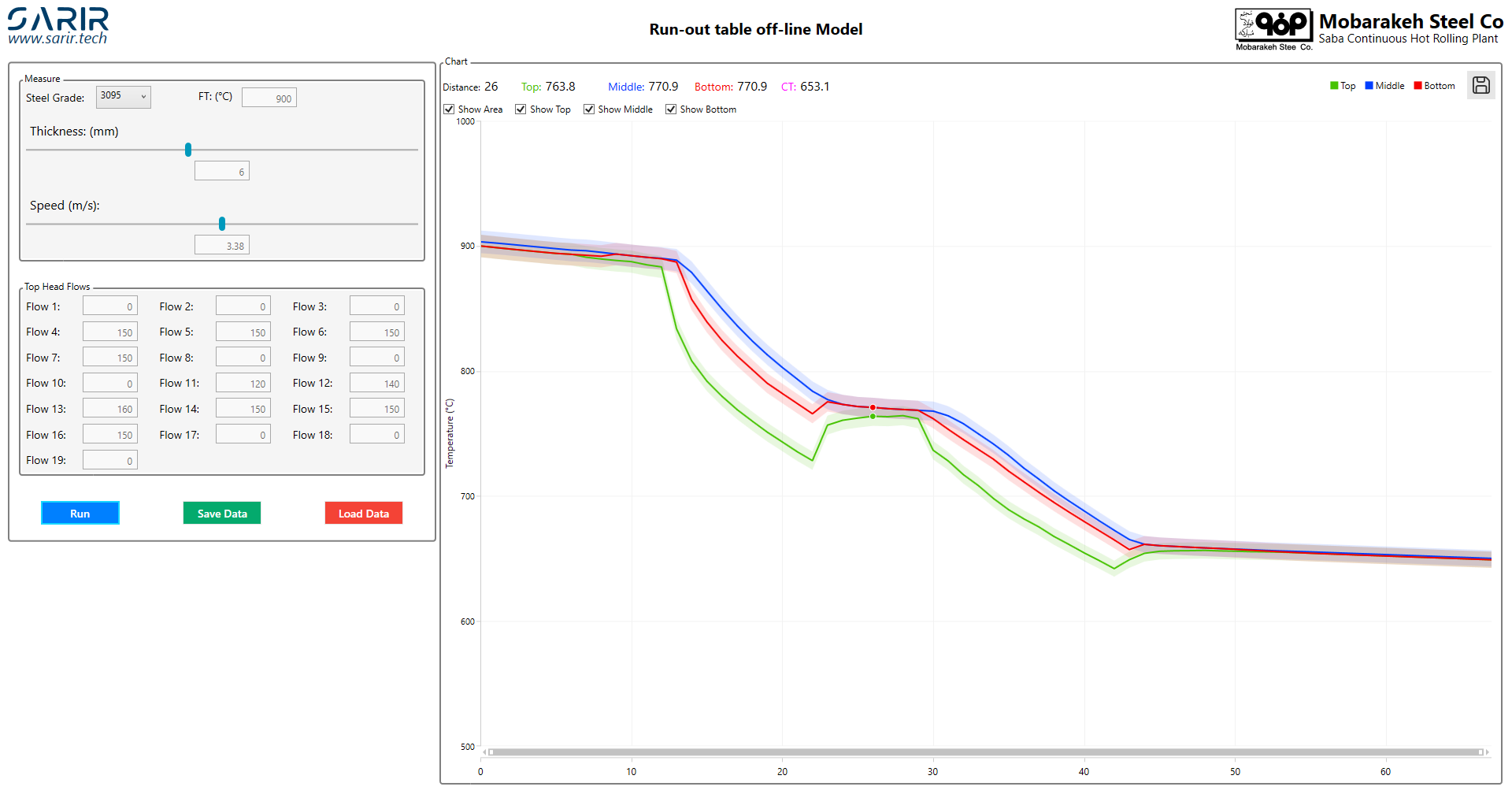

Saba steel run-out table includes 19 curtain showers in the upper part of the sheet and 19 point showers in the lower part of the sheet. All these showers have a control loop. Since the amount of water and water vapor on the sheet is extremely high along the entire path of the table, it is impossible to measure the sheet's surface temperature directly. To solve this problem, the heat transfer model is extracted, and the temperature of the sheet is estimated at all points based on the model with high accuracy.

Along with the online control software, an offline software was also designed and provided to the operating engineers to facilitate better analysis.

Purpose of Project

Adjusting the flow rate of the run-out table showers to achieve the desired temperature profile

Steps of Project

- Extracting the data required for modeling from the archive

- Checking the performance of level one

- Derivation of heat transfer model of Saba steel run-out table

- Adding adaptation to the inference model with deep learning methods

- Implementing a suitable controller for extracting the flow rate of showers

- Adding adaptation to the controller

- Adding feedforward to the controller

- Implementation of the model and controllers in the existing communication platform in Saba Steel (Danieli)

Used Technologies

- Heat Transfer Modeling

- Classical Control

- Optimal Control

- Algorithms and Adaptive Control

- Deep Learning

- Artificial Intelligence

- Implementing Control Algorithms and Deep Learning with C++

- Networking and Communications