Printing & Engraving System on Steel Slab, Billet, Bloom and Coil

Since 2022, the founding team of Sarir Company has decided to leverage its 13-year experience in the field of industrial printing and engraving machines, as well as its knowledge of ink production, to serve the metal and oil industries. In this regard, three product ranges were produced based on the needs of production lines.

In addition, this company localized all ink nozzles, laser engraving systems, and ink used in these devices. The ink produced by this company can be printed on hot sections up to 400°C in color and up to 750°C in silver color.

The three ranges of production devices of this company are as follows:

Ink spraying and Engraving on it

In this type of system, the product's cross-section is first colored by light ink, and then the color is removed by a laser engraving machine.

| Usage | Billet and Bloom (Hot and Cold) Slab (Hot and Cold) |

|---|---|

| Benefits | Possibility of printing logo, barcode, QRCode, and all kinds of text Possibility of printing directly on the product |

This system has an automatic nozzle washing system that prevents nozzle clogging.

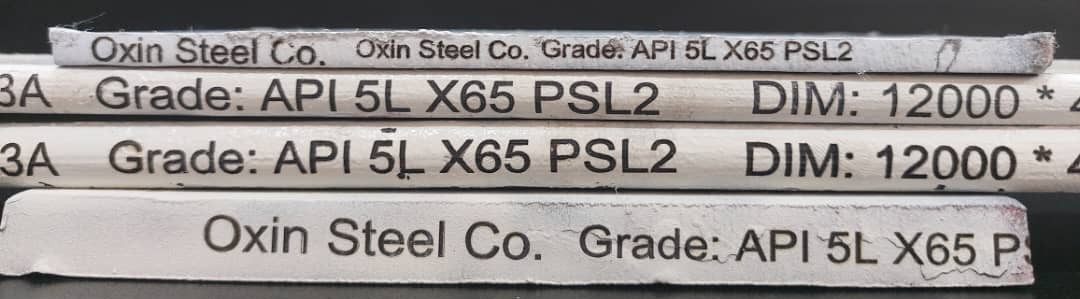

Direct Ink Spray

This type of system features a spherical robot arm and a single paint-spraying nozzle, which is moved by the robot arm in three dimensions. This system provides the possibility of printing on the body and side of the steel coil at the same time. Being equipped with an automatic washing system and the possibility of using localized ultraviolet inks are other features of this product.

The use of ink and ultraviolet lamps eliminates the need to wash the system and reduces the clogging of the nozzle to zero.

| Usage | Billet and Bloom (Hot and Cold) Slab (Hot and Cold) Sheet (Hot and Cold) Coil (Hot and Cold) |

|---|---|

| Benefits | Possibility of printing directly on the product Possibility of printing with large dimensions |

| Limitation | Limitation on printing details |

Laser Engraving and Welding

In this type of system, first, the desired specifications such as text, logo, barcode, and QRCode are engraved on a piece of metal sheet or fireproof paper in an isolated environment next to the production line, and then it is welded on the product by a robot.

| Usage | Billet and Bloom (Hot and Cold) |

|---|---|

| Benefits | Possibility of printing logo, barcode, QRCode, and all kinds of text |

| Limitation | Sheet cost Limitation on the size of engraving |