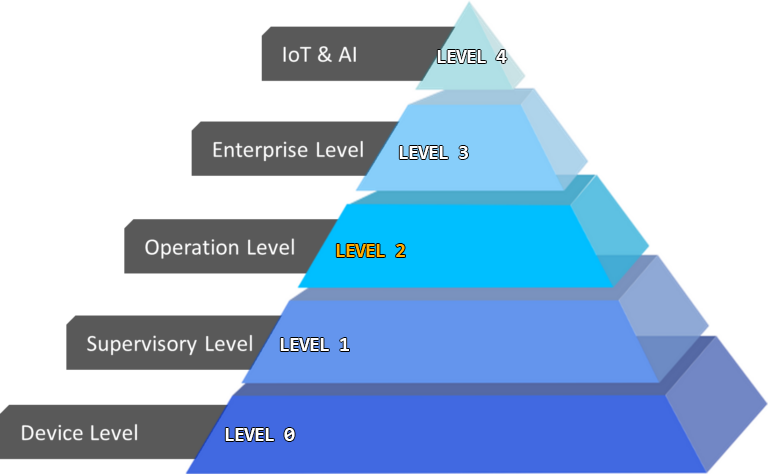

Level 2 Automation and APC Packages

Sarir Company, backed by a team of experts with deep technical knowledge and extensive experience in the steel and oil industries, enables the design and implementation of modeling, intelligence, and Level 2 Automation and APC (Advanced Process Control) in these industries, aligning with the Fourth Industrial Revolution (Industry 4.0).

This capability provides the following key benefits:

- Improved product quality

- Optimization of energy and raw material consumption

- Reduction of operational and maintenance costs

- Decreased production time and increased production line efficiency

The implementation of this project in the industry follows the steps below:

Step 1: Monitoring and Data Collection

For accurate modeling, model testing, and application of machine learning algorithms, valid real-time process data is required. Sometimes these data are available from existing sensors or historical databases, while in other cases, due to insufficient or low-accuracy data, temporary or permanent data acquisition equipment must be installed.

Components of this step include:

- Sensors: Measuring parameters such as sheet temperature, pressure, and fluid flow, sheet speed at various points along the production line.

- Data Acquisition (DAQ) Modules: Receiving sensor signals, converting them to digital data, and sending them to the central system.

- Data Monitoring and Display Modules: Designing graphical dashboards to monitor temperature, cooling shower flows, and vibration of different parts of the line. Operators can view real-time conditions and make necessary adjustments through these dashboards.

Step 2: Data Analysis

Level 2 data analysis and model development systems process real-time and historical data to reveal important patterns and relationships. This stage forms the foundation for intelligent decision-making and process optimization.

Sub-steps:

- Data Collection and Cleaning: Noise removal, normalization, and data quality enhancement.

- Data Analysis using Statistical and AI Algorithms: Applying neural networks, regression algorithms, and machine learning methods to identify hidden patterns, detect anomalies, and discover potential issues.

Step 3: Process Modeling and Model Development

At this stage, the process is modeled through physical equations and numerical simulations. Then, to cover uncertainties and complexities, machine learning is applied to real data. This sub-stage includes:

- Process modeling by solving governing equations and simulating them in relevant software

- Using machine learning algorithms on the acquired data to determine uncertainties in the model extracted from the simulation

- Developing the model using relationships between physical parameters such as temperature, flow rate, speed, and other parameters extracted from Step 2, as well as outputs from previous machine learning algorithms, to accurately represent process behavior.

The output of this step is a hybrid model combining physical simulations with AI algorithms to accurately represent process behavior.

Due to high computational requirements for CPU, GPU, and RAM, this step is usually executed on supercomputers.

Step 4: Digital Twin

A digital twin is a dynamic virtual version of the real process, enabling prediction, decision-making, and optimization.

Key components:

- Offline Model: Software provided to engineers to examine the impact of changes in each parameter and actuator on the process and to determine optimal setpoints for control loops. These models are simplified with machine learning algorithms for fast execution on personal computers.

- Prediction and Decision-Making System: Using historical data and identified patterns to predict future process behavior and send corrective instructions to controllers. This effectively reduces waste and prevents potential issues.

- Dashboard and Reporting System: Providing comprehensive real-time information and optimization results through management dashboards and analytical reports for operators and managers.

Benefits of using a digital twin:

- Ability to simulate various scenarios without risk on the actual production line

- Reduction of trial-and-error costs in processes

- Faster innovation in settings and control solutions

- Providing a platform for training operators and engineers in a safe, simulated environment

- Improved reliability and system stability through failure prediction and preventive maintenance

Step 5: Implementation

In this stage, the developed Level 2 software is deployed online. Real-time sensor and production line data are received, and setpoint values are sent to Level 1.

Advanced, robust, and adaptive control algorithms are then integrated to minimize the impact of disturbances and process variations.

If suitable hardware is not available, the infrastructure is first designed and implemented.