Slag Detector Machines

Slag-free transfer of molten steel is critical for prime or scrap and for profit or loss in producing high-quality steels. Regardless of whether it is for furnaces, ladles, or distributors: Large quantities of slag must never be transferred to the next vessel.

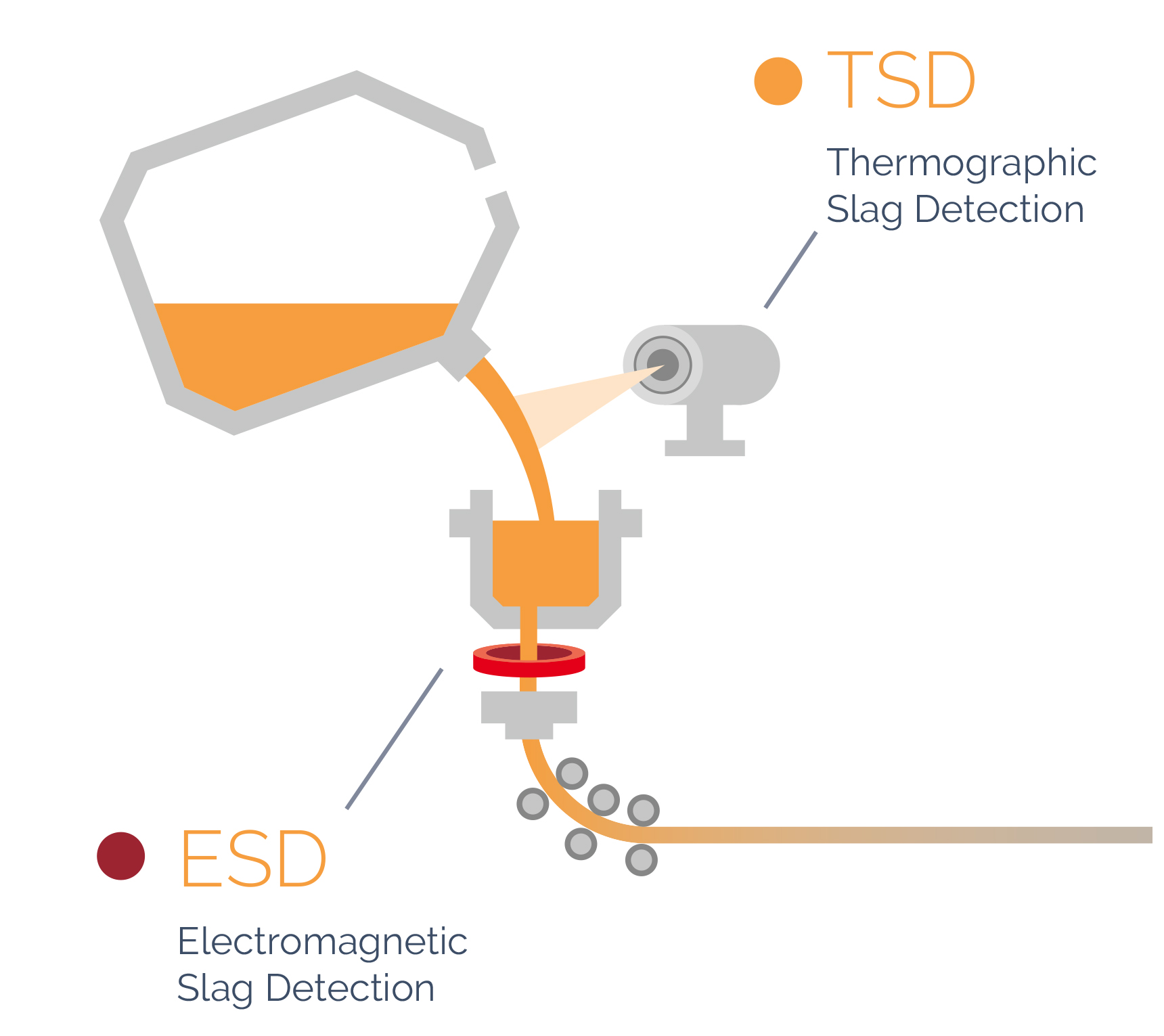

For this, Sarir Company has designed and produced two types of devices, which are:

- Electromagnetic Slag Detection (ESD)

- Thermographic Slag Detection (TSD)

As it is clear in the figure below, the electromagnetic type is suitable for the laders from the discharge floor and the thermographic type is suitable for furnaces and leaders from the discharge head.

Electromagnetic Slag Detection (ESD)

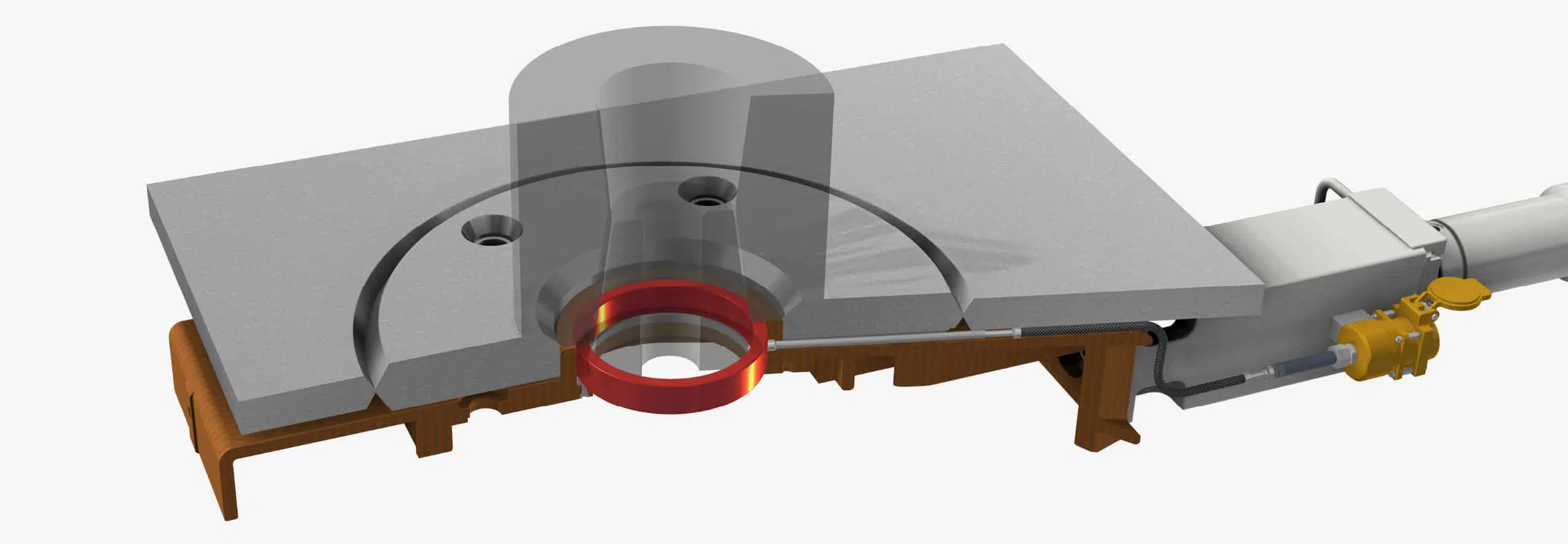

ESD Electromagnetic Slag Detection, positioned at the ladle bottom, sounds an alarm when slag flows through and automatically sends a signal to close the slide gate.

The sensor is installed in the outlet opening of the pot and through a transmitter installed in the field, it sends the characteristics of the melt passing through the passage of the pot to the terminal board and the slag detection system in the control room. This sensor works based on magnetic field and voltage induction from primary to secondary. The primary coil is excited by an AC electric current, generated by the slag detection system. The voltage of the secondary winding depends on the type of material passing through the bottle outlet. Therefore, the molten steel creates a different voltage compared to the induced voltage during the passage of slag, and the slag detection system reveals this difference.

Thermographic Slag Detection (TSD)

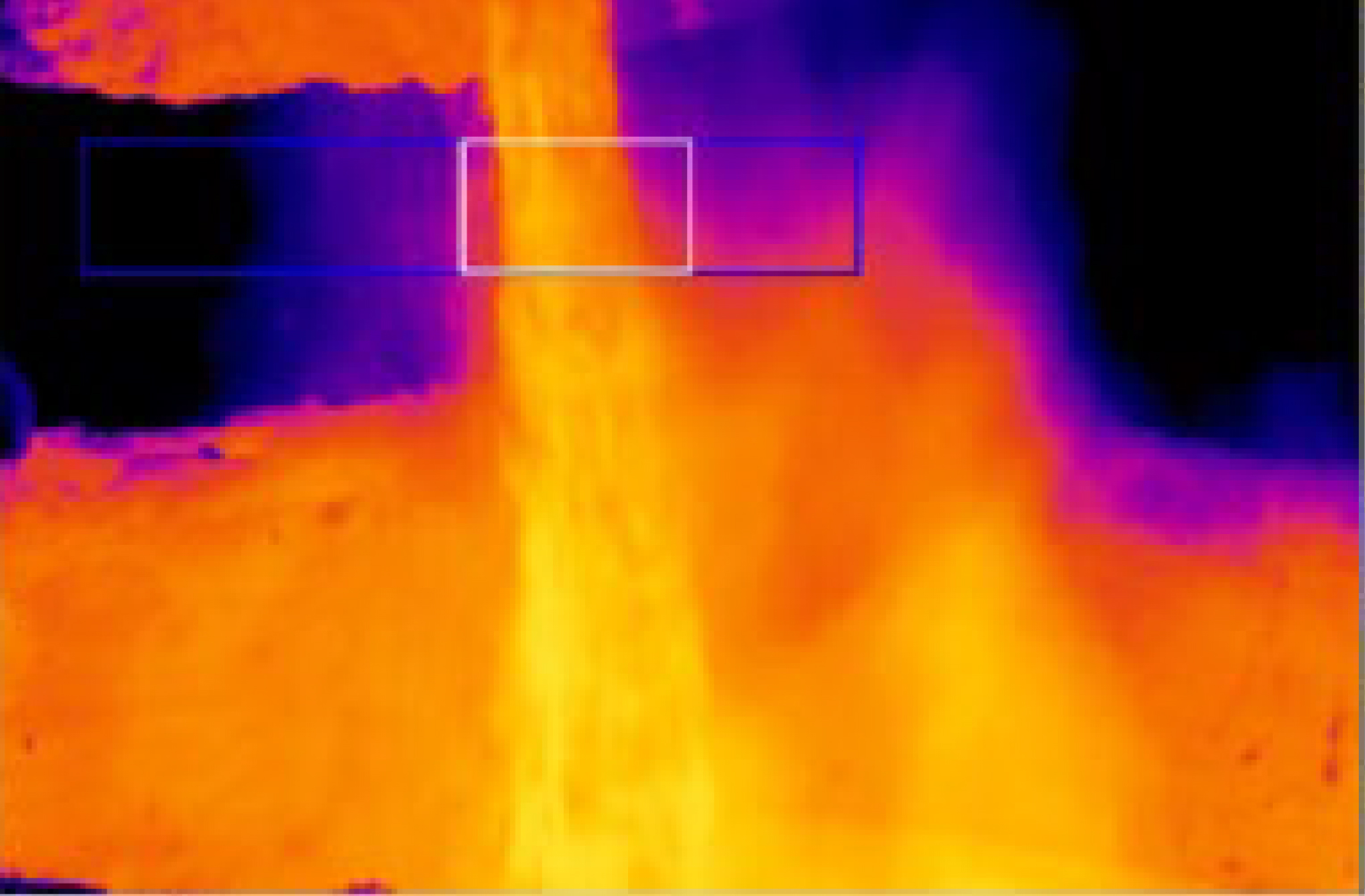

In this slag detection method, the molten material output is imaged by a thermographic camera. By processing these images, the percentage of slag in the molten material is detected and sent to the automation system.

The raw image from the infrared camera is linked with environmental parameters and evaluated in a high-quality industrial PC with the image processing software.

Advantages

- Product quality increases due to the automatic prevention of slag entering the production products in the casting line

- Increasing productivity and reducing the production cost due to clogging and cleaning

- Eliminate human error (which is unavoidable in a manual system)